Exciting News: Laser Welding Machine for Diamond Saw Blades and Core Drill Bits Coming Soon!

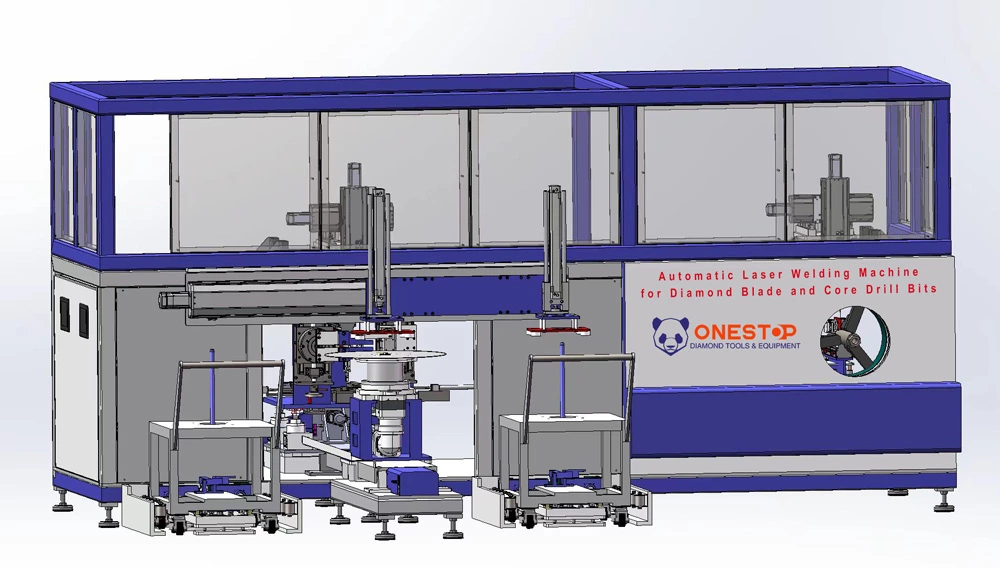

Onestop Diamond Tools Company is thrilled to announce the upcoming release of our latest product: the Laser Welding Machine for Diamond Saw Blades and Core Drill Bits, offering unprecedented precision and efficiency.

Principle of Laser Welding:

Laser welding harnesses the power of high-energy density laser beams as a heat source for an exceptionally efficient and precise welding method. The process begins with a laser generator producing the laser, which is then transmitted through optical fibers to the welding head. The welding head focuses the laser to irradiate and heat the contact surface between the substrate(blade blank or barrel blank) and the diamond segments. By controlling parameters such as laser pulse width, energy, peak power, and repetition rate, the substrate, and the tool's contact surface are melted, forming a specific molten pool that solidifies, bonding the substrate(blade blank or barrel blank) and the diamond segments together seamlessly.

Features of the Laser Welding Machine:

Our company introduces a revolutionary solution with the Laser Welding Machine for Saw Blades and Core Drill Bits. With this single-device investment, customers can now seamlessly switch between laser welding diamond saw blades and core drill bits, eliminating the need for multiple machines and optimizing operational efficiency.

Many small and medium-sized enterprises face fluctuating demands for laser welding diamond saw blades and core drill bits, often unable to meet full production capacity with existing equipment. This innovative machine addresses these pain points by providing an extremely cost-effective patented solution.

The machine streamlines operations by automating the welding process for saw blades. Employees load the conveyor belt with diamond segments in one go, and the welding process for saw blades, including fetching the diamond segments, loading the blade blank and unloading the welded saw blade, runs fully automated.

For drill pipe welding, manual barrel loading and unloading are required, while other operations such as segment picking and welding are automated. The machine is capable of producing saw blades ranging from φ300 to 1200 and core drill bits from φ20 to 350 thin-walled.

Technical Specifications

| Work Efficiency | 3500-4000PCS/8Hours |

| Welding Range of Saw Blades | 300mm-1200mm |

| Welding Range of Core Drill Bits | 20mm-350mm |

| Suitable Power | 380VAC、50HZ |

| Motor Power | 7.6KW |

| Laser Power | 3.0kW |

| Suitable Air Source Pressure | 0.40~0.60 MPa(0.5MPa for the best) |

| Dimensions | 4.2mx(1.5+1.38)mx2.0m (LXWXH) |

Quality Assurance:

To ensure the highest standards of performance and reliability, the Laser Welding Machine incorporates components sourced from top domestic and international brands for light sources, welding heads, servos, touchscreens, modules, and PLCs. Additionally, customers have the flexibility to specify preferred brands for customization according to their requirements.

Availability:

The Laser Welding Machine for Diamond Saw Blades and Core Drill Bits will be available for purchase starting 15th, March. For inquiries, demonstrations, or pre-orders, please contact sales@onestopdiamondtools.com or whatsapp: +86 13882641960(Peter).

Don't miss out on this groundbreaking advancement in laser welding technology. Stay tuned for more updates and announcements as we approach the official release date.

Русский

Русский Español

Español