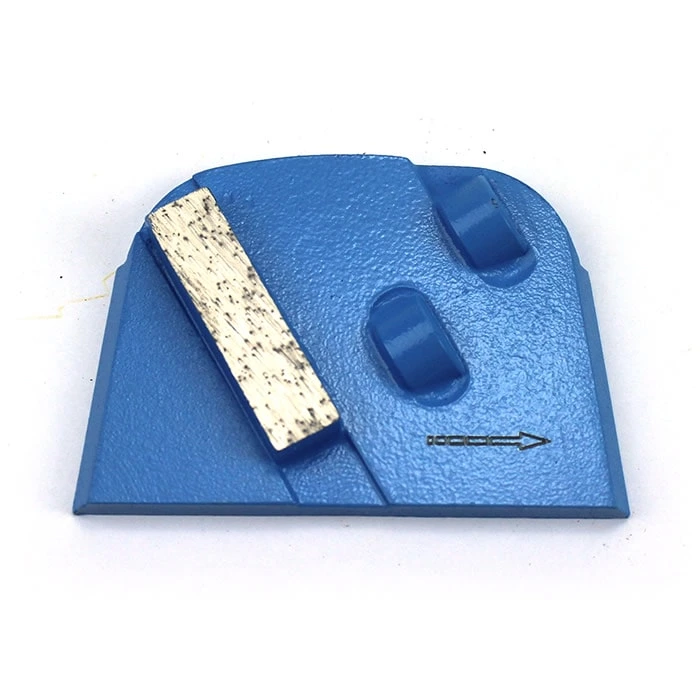

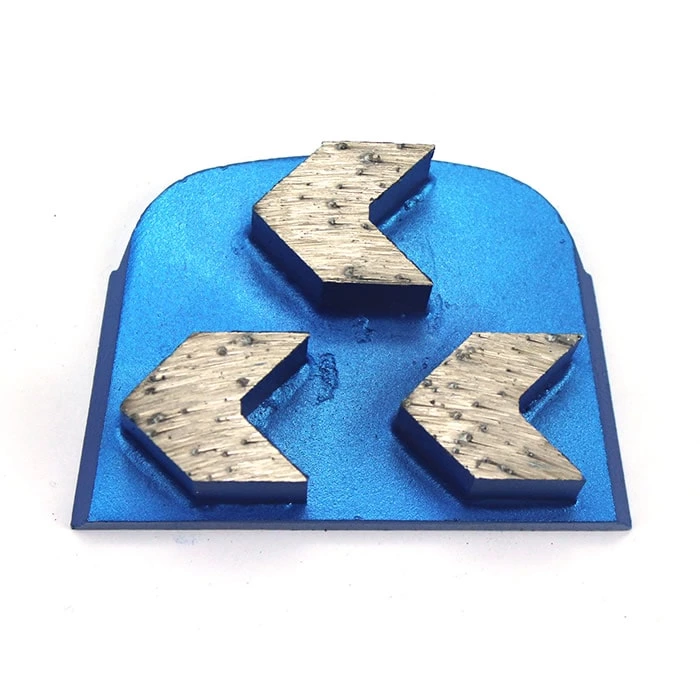

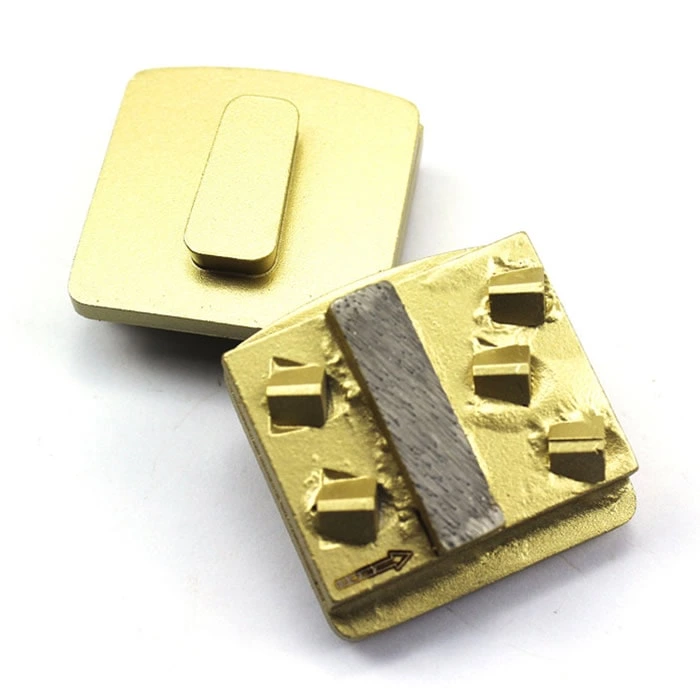

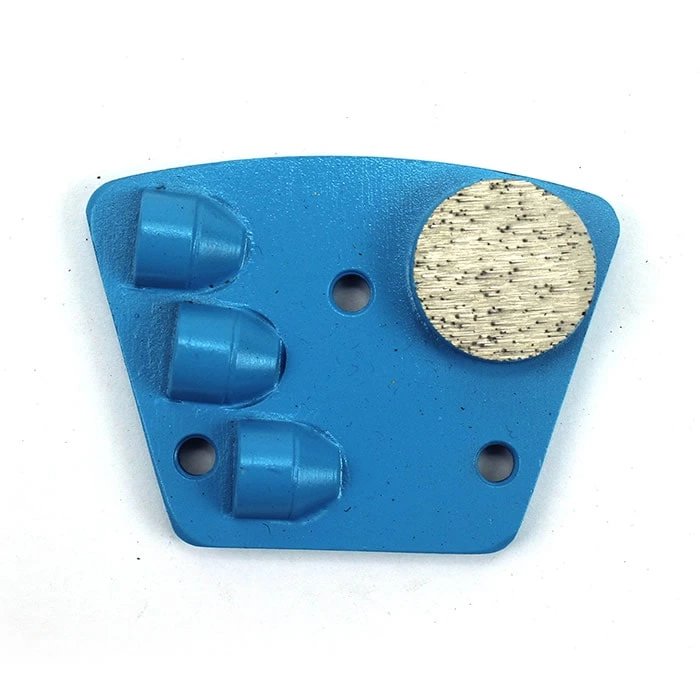

The concrete floor grinding diamonds commonly known as floor grinding shoes are designed for use on various types of floor grinding machines, for grinding concrete or terrazzo floors. They come in a variety of shapes and sizes to be used on different types of flooring. Some of the most popular brands of floor grinding machines include HTC, Husqvarna, Lavina, ASL, Scanmaskin, Klindex, etc.

Types of Concrete Floor Grinding Diamonds

There are two primary types of concrete floor grinding diamonds: metal bond and PCD. Metal bond diamonds are typically used for general-purpose grinding and PCD diamonds are used for more aggressive grinding and floor coating removals.

Metal Bond VS PCD Types

- The metal bond concrete floor grinding shoes are equipped with sintered diamond grinding segments, designed for grinding concrete floors. PCD types use PCD only or PCD + sintered diamond segments, effective for removing floor coatings such as resin, epoxy, glue, paint, etc.

- Most metal bond concrete grinding diamonds use copper welding (brazing), but the PCD tools require silver welding.

Diamond Grits

When purchasing metal bond diamond grinding shoes, there are two aspects you need to confirm: the diamond grits and the bond types. Diamond grit refers to the standard size of diamond particles. Different countries have different standards.

The bigger the number of diamond grit, the smaller the size of the diamond particles. Therefore, if you want rough grinding on your concrete, you need to choose a small diamond grit. If you want a fine grinding, choose the bigger one. Generally, OneStop offers diamond grits (used for grinding) ranging from 6# to 220#.

Bond Types

Bond type selection is based on the hardness of the concrete being ground. Different bonds are used for different levels of hardness. As concrete is an abrasive construction material, the softer the concrete, the more abrasive it is. Therefore, a harder bond is required. The table below outlines the relationship between bond types and concrete hardness:

| Hardness of Concrete | Xtremely Hard | Very Hard | Hard | Medium | Soft | Very Soft |

|---|---|---|---|---|---|---|

| PSI | 6500-9000 | 5000-7000 | 4000-5000 | 3000-4000 | 1500-3500 | 1000-2000 |

| MPA | C50-C65 | C40-C55 | C30-C50 | C20-C40 | C15-C25 | C10-C20 |

| Code of Bond | XSB | VSB | SB | MB | HB | VHB |

PCD Floor Coating Removal Tools

The most popular shape of PCD tool for floor coating removal is the quarter-round. Other shapes include the round, half-round, and 1/8 round. PCD tools may also come with sacrificial diamond segments or tungsten carbides to help with the removal process.

The Connections and Adapter

The four main types of connections are:

- Pins + Magnet (like ASL)

- Bolt-on (like normal trapezoid floor grinding shoes)

- Quick change system (like HTC diamond tooling, Redi-lock diamond segments, Lavina metal bond diamodns)

- Velcro (like the concrete grinding pucks)

We can integrate different connection types to make them compatible with multiple types of floor grinders. For example:

- Trapezoid grinding diamonds with six holes - three 9mm unthreaded holes for ASL grinders and three threaded holes for other floor grinders.

- Lavina grinding diamonds with three 6mm threaded holes - Lavina quick-change system for Lavina grinders and three threaded holes for other floor grinders.

When integrating the connections, we also have to consider the number and layout of the grinding segments. Sometimes, there is no space to integrate 2 connections on one floor grinding shoe. However, there is another way to use other grinding diamonds on a specific floor grinding machine - To use an adapter.

Get A Quote

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Русский

Русский Español

Español