Welding Technologies of Diamond Saw Blades

On the market, different types of diamond saw blades are used for different purposes. You may have heard terms like hot-pressed diamond blades, laser welded blades, but what’s the difference between them? Some of the terminology is confusing, such as cold-pressed and hot-pressed diamond blades.

This article will introduce you to the main welding methods of the diamond saw blade, so that you can better understand them and choose the saw blades that meet your needs.

There are three types of diamond saw blades according to the different welding technologies:

- Sintered Diamond Saw Blade

- Cold-pressed sintered diamond blade

- Hot-pressed sintered diamond blade

- Welded Diamond Saw Blade

- High-frequency welded blade

- Laser welded blade

- Vaccum brazed blade

- Electroplated Diamond Saw Blade

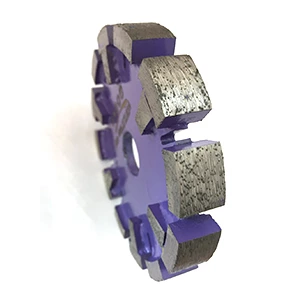

Sintered Diamond Saw Blade

There are two types of sintered diamond blades: cold-pressed and hot-pressed. We usually refer to them simply as cold-pressed and hot-pressed blades, but both types are technically sintered.

The sintered blade is very thin and has a small diameter. It is often used on small cutting devices, such as angle grinders. The sintering process of this blade is completed the in furnace, which has a very high production efficiency.

The main difference between cold-pressed blades and hot-pressed blades is that hot-pressed blades are sintered under pressure, while cold-pressed blades are not. This is why hot-pressed blades have a higher density and longer lifespan. However, cold-pressed blades have a faster cutting speed.

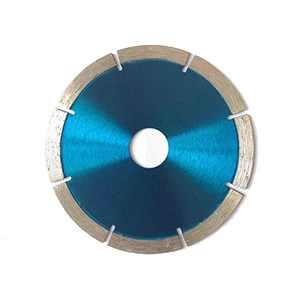

Welded Diamond Saw Blades

Welded diamond saw blades are the blades that use welding technology to fix the segments on the blank core. There are mainly 3 different types:

- High-frequency welded blade

- Laser welded blade

- Vacuum brazed blade

High-frequency Welded Blades

High-frequency welded blades are diamond blades that use copper solder or silver solder as a welding medium and are heated by a high-frequency power supply to fix diamond segments on the blank blade.

The welding strength of copper solder is higher than silver solder. It depends on which solder you use. Copper solder has a higher melting point and is used more often on blades designed to cut hard materials like granite and concrete, while silver solder melts at a lower temperature and is better for cutting soft materials like marble.

Laser Welded Blades

Laser welded blades are diamond blades that use laser welding. It does not require any welding medium but melts the contact area between the segment and the blank blade with a high-temperature laser beam, forming a metallurgical bond.

Laser welded blades are mainly used for cutting concrete, reinforced concrete, asphalts, metal, etc. Such materials require a higher welding strength to avoid the segment falling off during the cutting.

There is one thing that should be noted: the segments and blank blades are different from those used for high-frequency welding. Segments for laser welding have a special bottom layer, and the blank blade for laser welding has low carbon content, such as 30CrMo type.

Vaccum Brazed Blades

Different from other welded blades, vacuum-brazed diamond blades have no bonded-diamond segments and all the particles are on the exterior cutting edge of the blade. There are mainly 3 steps of vacuum brazing.

- Coating the solder alloy on the blank blade

- Arranging the diamond particles on the solder layer

- Making the welding in a vacuum brazing furnace.

Vacuum brazed blades are typically able to cut through a wide range of materials, such as stone, concrete, glass, tile, steel, etc.

Electroplated Diamond Saw Blades

Electroplated diamond saw blades are diamond blades that use electroplating technology: the diamond particles are attached to the substrate by electroplating.

The electroplating is most commonly used on small cutting discs for cutting soft materials such as marble and limestone. It is mainly suitable for stone, ceramics, shells, glass, jewelry, jade, semiconductor materials, and cemented carbide materials.

The electroplated diamond saw blades can be very thin and suitable for fine cutting. However, the blades have a short life and the electroplating process will cause environmental pollution.

Русский

Русский Español

Español