How To Choose Floor Grinding Shoes

TABLE OF CONTENTS

Floor grinding shoes, also called floor grinding diamonds or floor grinding segments, are tools used on different types of floor grinders for floor surface preparation. There are generally two types of floor grinding shoes: metal bond shoes for concrete/terrazzo floor grinding, and PCD shoes for floor coating removal.

They are constructed with a steel base and PCD/segments welded to it. Metal bond shoes are made with copper high-frequency welding, and PCD-type shoes use silver welding.

When purchasing either of the two types of floor grinding shoes, what should you be aware of, and how should you make your selection? After reading this guide, you should be able to find the answers. This guide is designed for new buyers, but I believe there is some valuable information here for regular customers as well.

General Ideas When Choosing Diamond Tools

The floor grinding shoes are one of the diamond tools. When purchasing diamond tools, there are three main aspects we should take into consideration:

- what machines and models we use.

- what materials we process, such as granite, marble, concrete, reinforced concrete, and more.

- The tool itself, such as the bonds type and diamond grits of the floor grinding shoes.

It means that regardless of the tools we select, the tool should be appropriate for the machines we use as well as the material to be processed.

First, in order to purchase the appropriate type of floor grinding shoes, we should be aware of which grinding machines you are using. If you are an end user, this is clear. However, if you are a reseller planning to expand your product range with new tools, you should research which machines are popular in your market first. This will give you an indication of which tools will also be in high demand. The tools always follow the machines.

Here are some popular floor grinders on the global market for your reference: HTC, Husqvarna, Lavina, ASL, Klindex, Blastrac, EDCO, Scanmaskin and more.

Husqvarna Floor Grinding Machine

Lavina Floor Grinding Machine

ASL Floor Grinding Machine

Klindex Floor Grinding Machine

EDCO Floor Grinding Machine

Secondly, confirm the purpose of the tools you are going to use. If you want to grind a concrete floor or terrazzo floor, you should use metal-bonded floor grinding shoes. If you want to remove floor coatings, then the PCD type is your best option.

Buying Metal Bond Shoes for Concrete/Terrazzo Floor Grinding

The segments are the functional part of metal bond shoes. From the appearance of the segments, we can measure the segments in 3 aspects: the segment shape, numbers and layout.

The Segment Shape

Different segment shapes produce different results when grinding. The classic and most used segment shapes are rectangle (bar), round (button), and arrow.

2 Segment Bars HTC Grinding Shoes

3 Arrow Segments HTC Grinding Shoes

2 Segment Buttons HTC Grinding Shoes

Some customers may choose the segment shapes by habit. What Onestop suggests is:

- Arrow segments for rough grinding

- Rectangle segments for medium grinding

- Button segments for fine grinding

Onestop not only offers the three classic grinding segments, but we have developed different other shapes, such as zigzag, hexagonal, H shape, S shape, and Z shape. They satisfy different requirements of our customers in regards to shape, but also have different applications. The zigzag segment, for example, can be used not only for rough grinding but also for thin floor coating removals because of its multi sharp angles.

The Segment Numbers

The segment numbers influence the lifespan and grinding results.

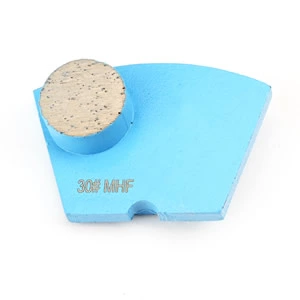

1 Round Segment Grinding Shoes

2 Round Segments Grinding Shoes

3 Round Segments Grinding Shoes

When the same machine is used, floor grinding shoes with fewer segments will have more pressure on each segment. This results in a deeper cutting depth and quicker consumption. Therefore, fewer segments are used for more aggressive grinding.

However, a large number of segments results in a smaller average pressure being distributed on each segment. This produces a thinner grinding depth and gives the shoes a longer life and higher grinding efficiency.

For aggressive grinding, we recommend fewer segments. For general grinding, we recommend more segments.

The Segment Layout

Even when the same numbers and shapes are involved, the layout can be different. Sometimes, the layout can be influenced (limited) by other factors, such as the placement of connection holes.

12 Segmented Turbo Klindex Shoes

12 Segmented (6 pairs) Klindex Shoes

12 Segmented Klindex Grinding Shoes

Here is a good example of the klindex grinding rings. We have developed different layouts of the same number of rectangle segments, to meet the diverse needs of our customers.

The Steel Base of The Grinding Shoes

As I mentioned before, the brand and model of the floor grinding machine determine the type of steel base. But sometimes, we can make a small change to the steel base to make it more unique and appealing than other products on the market.

Here is an example of HTC grinding shoes. There are 2 holes in the base, which is different from regular HTC shoes.

Normal Steel Base of HTC Grinding Shoes

Hollow Steel Base of HTC Grinding Shoes

From the inside of the segments, there are two things we have to confirm: the segment bonds and diamond grits.

Segment Bonds

The segment bonds correspond to the hardness of the concrete. Onestop diamond tools have 6 different bond levels to suit different hardness of concrete. Please check our standard as follows:

| Hardness of Concrete | Xtremely Hard | Very Hard | Hard | Medium | Soft | Very Soft |

|---|---|---|---|---|---|---|

| PSI | 6500-9000 | 5000-7000 | 4000-5000 | 3000-4000 | 1500-3500 | 1000-2000 |

| MPA | C50-C65 | C40-C55 | C30-C50 | C20-C40 | C15-C25 | C10-C20 |

| Code of Bond | XSB | VSB | SB | MB | HB | VHB |

We offer the extremely soft bonds necessary for grinding extremely hard concrete (Morse hardness from 6500 to 9000).

If this is your first time purchasing our grinding shoes and would like to try them out, we recommend you select the medium bond, as it is the most commonly used.

Diamond Grits

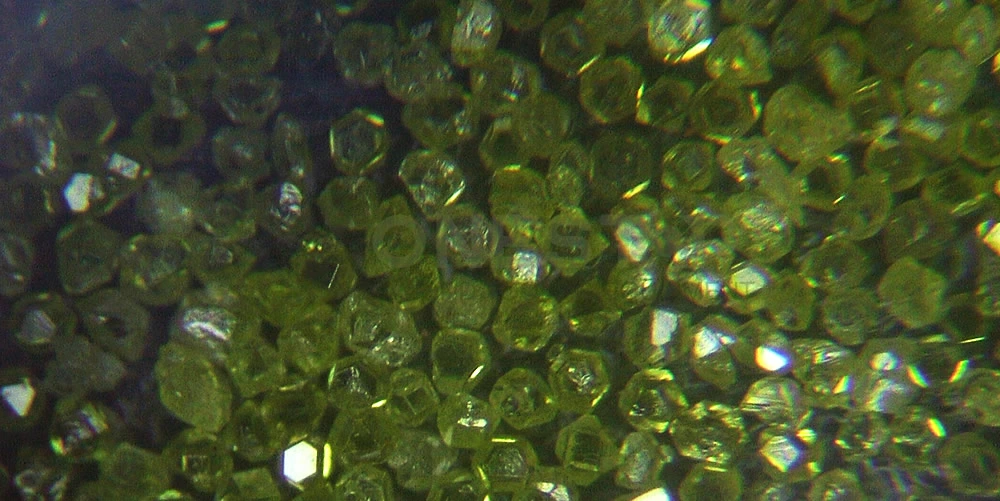

Diamond Particles Under The Microscope

Diamond Particles Under The Microscope

Diamond grits, also called segment grits sometimes, are the standard for the size of diamonds. Lower diamond grits refer to bigger diamond particles. The diamond grits of the grinding segment should be chosen based on the grinding level you want. The diamond grits for concrete grinding are from 6# to 220#.

- For rough grinding, we recommend the grits range from 6# to 16#.

- For medium grinding, we recommend the grits range from 30# to 80#.

- For fine grinding ,we recommend the grits range from 120# to 220#.

Note: different segment shapes may have different recommended diamond grit ranges. Please consult with the manufacturers or the suppliers to learn more.

Buying PCD Floor Grinding Shoes

PCD shoes are ideal for removing floor coatings, like epoxy, glue, paint, varnish, and more.

PCD Shapes, Numbers and Layouts

There are three main types of PCD shoes that are used- round PCD, half-round (1/2) PCD, and quarter-round (1/4) PCD. We also use eighth (1/8) PCDs on some grinding shoes.

Full Round PCD

Half Round (1/2) PCD

Quarter Round (1/4) PCD

Eighth Round (1/8) PCD

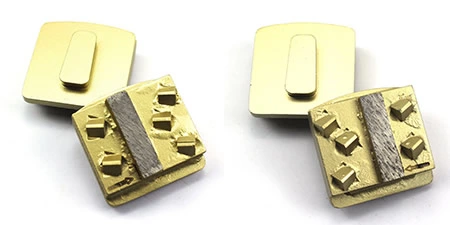

Some PCD shoes are also equipped with sacrificial metal bond segments to help with the grinding process, such as the segment bar, and arrow segment.

PCD Welding Places and Directions

Unlike the copper welding method used on metal bond shoes, we use silver welding on PCD shoes. This is because PCD has a lower melting point and can't withstand copper welding.

The segments on metal bond grinding shoes are welded onto the steel base by human judgement. While for PCD grinding shoes, the position of PCDs and sacrificial segment has already fixed before welding.

Steel Bases of Trapezoid PCD Floor Coating Removal Tools

The segments are welded onto the steel base by human judgement, while the PCDs have fixed positions. Check the difference between the blank steel base of metal bond shoes and PCD shoes.

There are two things to consider when buying PCD shoes:

The Welding Places: Obverse VS Reverse

There are 2 different welding ways for the 1/4 round or 1/8 round PCD chips: One involves welding the corner side and exposing the round edges for grinding, which we called obverse welding.

Obverse Welding of 2 Quarter Round PCDs

Reverse Welding of 2 Quarter Round PCDs

The other involves welding the round edge and exposing the corner side for grinding, which we called reverse welding. The reverse welded PCD shoes are more aggressive compared to the obverse type. They have sharp corners and smaller contact areas with the floor, so they exert more pressure on the floor.

The Welding Directions

Different Welding Direction of Quarter Round (1/4) PCD

Different Welding Direction of Half Round (1/2) PCD

Different Welding Direction of Husqvarna PCD Shoes

Different Welding Direction of HTC PCD Grinding Shoes

There are 2 PCD directions- rotating clockwise or unclockwise. You should select the right direction based on your floor grinders. The working direction of the PCDs should be the same as the rotating direction of the holder plate on your floor grinders.

Take Away: Four Things We Should Take Into Consideration For Grinding Shoes

To get satisfied floor grinding shoes, there are 4 things we should take into consideration: The segment formula, the size, the welding strength, and the packaging.

The Segment Formulas

The segment formulas are the fundamental element to the grinding shoes' quality. It essentially decides if the tool is suitable for your grinding project or not. Choose the right segment bonds and diamond grits for your job.

The Size

The size we are discussing refers to the dimensions of the steel base including the connection holes. It determines whether the tools fit onto the floor grinders perfectly. If the size is inaccurate, the tool will become loose when connected to the machine. Sometimes we can use them despite the looseness, or use them after making minor adjustments. However, the worst outcome is that the shoes cannot be used at all and require significant adjustments, which would delay our construction period.

The Welding Strength

The welding strength is also crucial. If it is weak, the segments may fall off the steel base during work. but even if the welding strength is strong enough, the same things sometimes will happen by accident, such as meeting hard materials like metal.

The Packaging

The packaging of the grinding shoes is also something to take notice of. Inside the packing, each floor grinding shoe should be separated from others to protect the diamond segments from being cracked. Outside the packing, we should use reliable packing materials, to make sure all the grinding shoes are in good condition when the customer receives them.

Русский

Русский Español

Español