Grinding Paths Of Floor Grinding Machines

Floor grinding machines, also called floor grinders, are excellent for grinding or polishing concrete floors or terrazzo floors, using different types of floor grinding shoes. Some companies have even developed new diamond tooling to grind wood floors, such as HTC company.

We all know that floor grinding shoes are the main factors to determine what the floor surface finish is like. It’s absolutely true but do you aware that the floor grinding machines also matter?

After reading this article, you will get what are the working paths of different types of floor grinders and how they affect the finish indirectly. The grinding path pictures are made through computer simulation and each head's grinding path use a different color to recognise.

Here I want to talk about 5 different paths which are created by 3 types of floor grinders, from simple to complicate:

- Single head floor grinders

- Square floor grinders with 2 and 4 heads

- Round floor grinders with 3, 4, and 6 heads

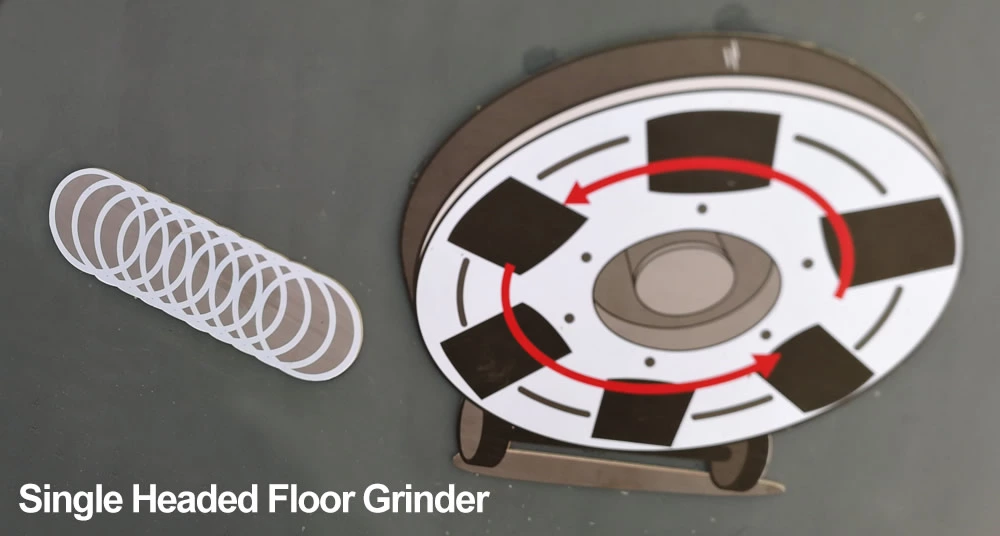

The Grinding Path of Single Headed Floor Grinders

The grinding path produced by a floor grinder with a single large diamond plate is typically the simplest type. Most floor grinders of this size are 250mm or less, such as 240mm Klindex grinders, 250mm EDCO grinder, and other similar grinding machines.

The single-headed grinder leaves a single, straight grinding path, as seen in the picture. It is a good choice for small projects and can be used for edge grinding or polishing.

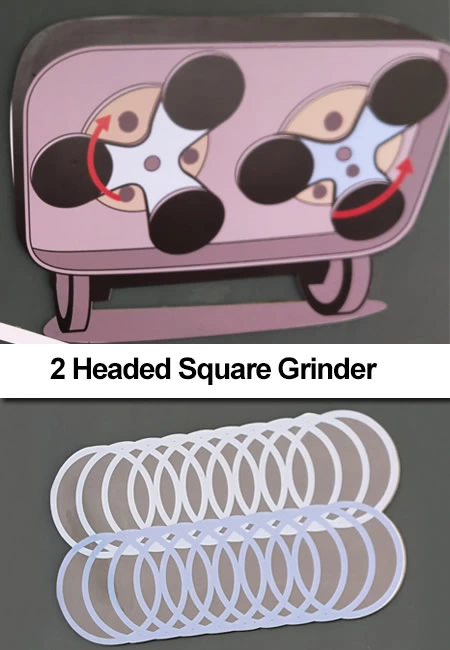

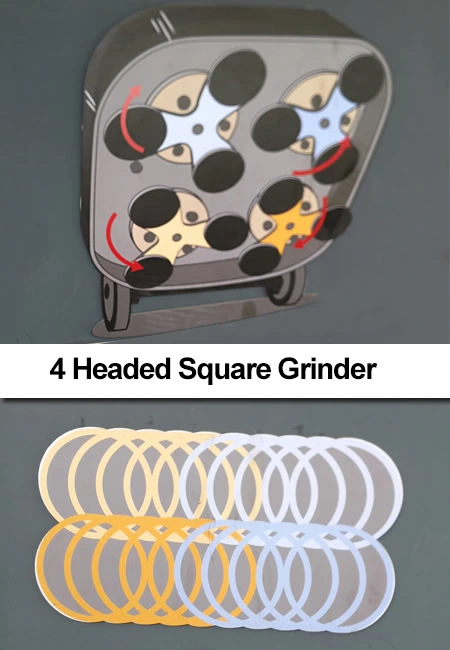

The Grinding Paths of Square Floor Grinders

Square floor grinders have a square-shaped grinding base. The most common type is with two or four counter-rotated heads. To get a full grinding without any gaps, the head(holder plate) is designed to extend in three directions and adjacent heads have a small overlapped grinding area.

Grinding Path of 2 Headed Square Floor Grinder

Grinding Path of 2 Headed Square Floor Grinder Grinding Path of 4 Headed Square Floor Grinder

Grinding Path of 4 Headed Square Floor GrinderFrom the grinding path pictures, we could see that both 2 or 4-headed square floor grinders will leave 2 columns grinding paths, but the 4 heads type has a larger grinding area and makes a more efficient grinding job.

The Grinding Paths of Round Floor Grinders

Different from square floor grinders, round floor grinders have a main rotating disc and several small rotating discs (heads), like 3, 4, and 6 heads. The small rotating heads are completely round plates and driven by the main disc, which is called the planetary method.

For round grinding machines, all the heads of 3 or 4 headed type go in the same direction, while the 6 headed types are different- any 2 adjacent heads are counter rotated.

Grinding Path of 3 Headed Round Floor Grinding Machine

Grinding Path of 3 Headed Round Floor Grinding Machine Grinding Path of 4 Headed Round Floor Grinding Machine

Grinding Path of 4 Headed Round Floor Grinding Machine Grinding Path of 6 Headed Round Floor Grinding Machine

Grinding Path of 6 Headed Round Floor Grinding MachineAs the picture shows, the grinding paths created by round floor grinders are entirely distinct from square grinders and much more complicated. Each head leaves a different grinding path, but all the paths together can be seen to form four main grinding circles. The more grinding heads there are, the denser the grinding path.

From single-headed, square, to round type, the floor grinders are more and more advanced and more functions are added, such as self-propelled, remote control, memory system, MCS(mist cooler system), etc. We can imagine that, in the future, the floor grinders will be smarter and smarter. With the technology of AI and 5G, someday grinding robots may be a reality.

Русский

Русский Español

Español